CFM-04 Servo Modular Counting and Ffilling Machine

Scope of Application

The machine is used for split charging of counting and flling suitable for varieties of tablets, soft and hard capsules, pills and other solid granules in the pharmaceutical, food, healthcare product and candy areas, etC.

Advantages & Features

•Utlile the moduar design cofigured for idividual module operating at indepedent electrical cntrol,Complete servo feeding at constant flow,3-level vibration segregation,electronic counting and servo sluice flling.

•Utlize the sloped silo design,in which the vibrating disc takes no load.The straight servo moyor is set discharge at constant flow in specified intervals.The silo vrating disc operates steadily without upset.Maintain real-time communication between the feeding servo motor and sluice servo motor. Perform real-time feeding flowrate in response to filling speed. Thus, assure steady operation without seizing.

•Utilize 3-level vibrating disc made in Germany, thus assuring steady vibration and quick response to startup/shutdown.

•Use a vibrating disc totally made of aluminum, whose surface is ubject to hard anodizing. It is abrasion resistant, and easily interchangeability.

•The Truking's tailor-made sluice straight servo motor operates with quick response, in which the speed curve can be varied, and the,operation status can be monitored,thus eliminating jamming or ejection.

•Utilize a totally air-tight design preventing dust penetration into the vibration chamber.

•Utilize the infrared counting control panel and dust proof optimized design;eave-type design conducive to controlling dust adhesion on the sightglass,thus alleviating cleaning workload.

•Provide a dust collection system covering the entire silo, 3-level vibrating disc, electric eye box, sluice,integrated piping dust collection design to eliminate dust penetration,

thus complying with GMP’S hygiene requirements.

•Utilize a double gate design conducive to coordinated operation in storage and discharging. Thus, eliminate seizing at the nozzle and improve flling efficiency.

•Start servo filling as the screw moves into the bottle. Perform Beckhoff motion control.The machine steadily operates at high speed with EtherCAT bus protocol.

•Vary the machine height by means of motor to deal with bottles at different height,thus fcilitating efficient manpower input.

•An individual module electrical board may be separately pulled out.The entire module may be moved out along the guide rail to facilitate cleaning and maintenance.

•Provide tool-fee quick change of scew and nozzle, which may be completed in less than 10min.

•Optionally, provide an online camera detection system for removal of broken pills.

•Use the transparent tempered glass protection door and low-counter designs. Plus,application of high-quality stainless steel and aluminum alloy can help assure uniform style, create a clean and tidy environment and provide easy access to view. Provide machines of latest version.

•Provide a l2" screenn conducive to ergonomics-based HMI operation

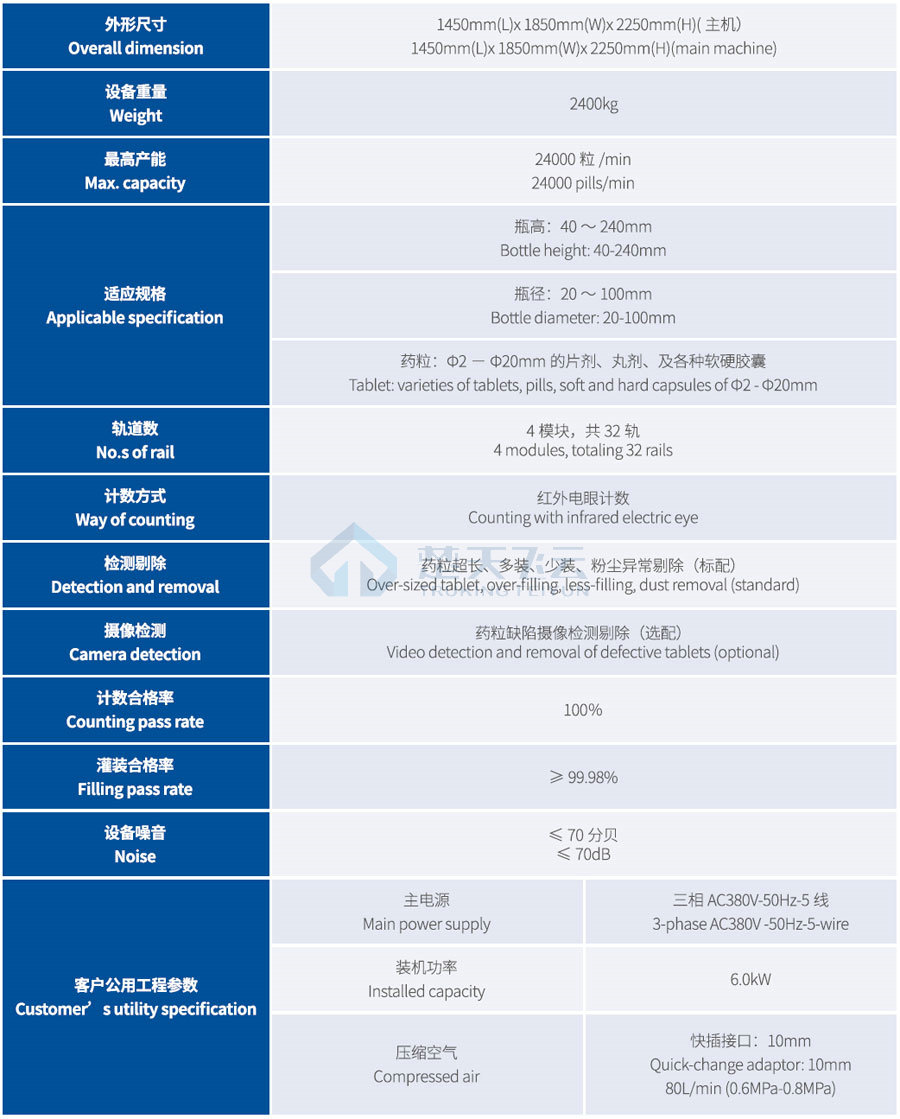

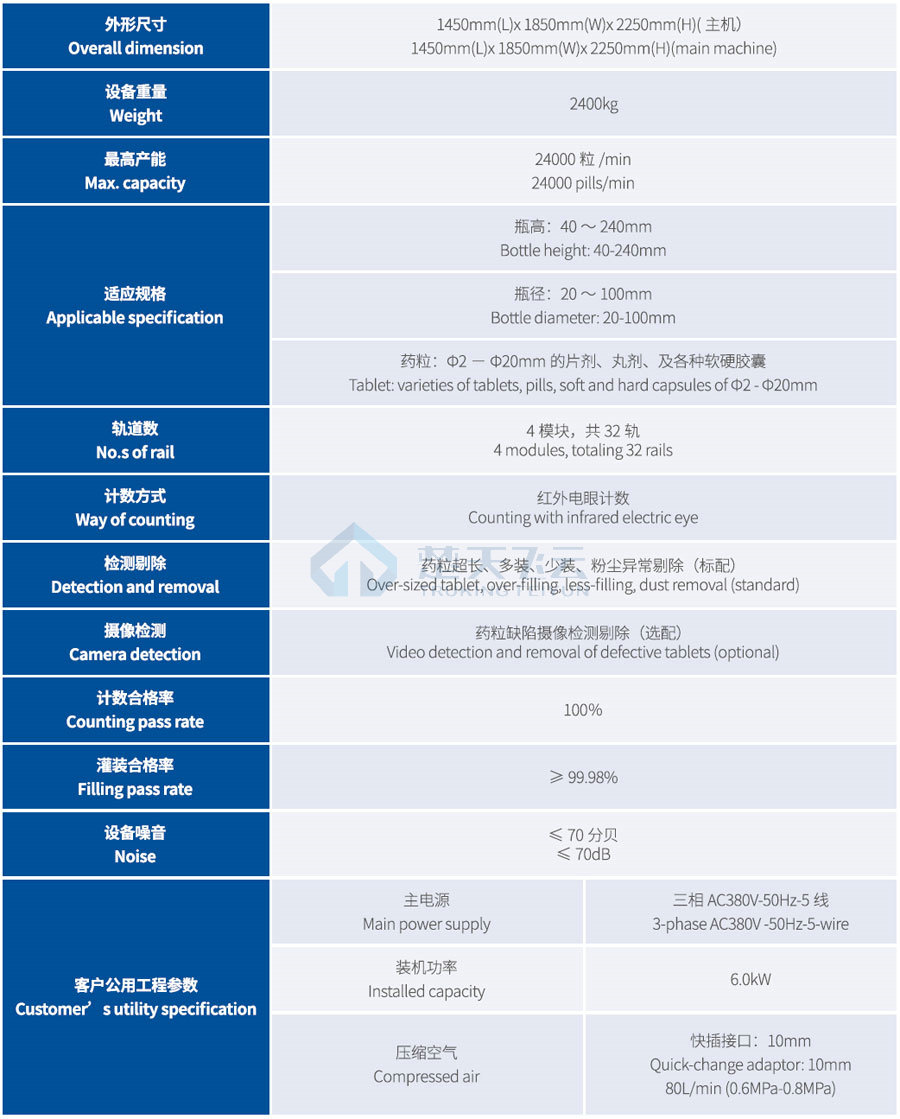

Models Technical Parameters