Products Search

Product recommendation

NJP3200 Full-Automatic Capsule…

NJP2200 Full-Automatic Capsule…

SP-L12, 12-column Stick Packing Machine for Liquids

This production line is applicable to quantitative stick packaging of various fluid substances such as oral liquid, mouthwash and oral thick paste. It is widely used in the pharmaceutical, healthcare, food, daily chemical areas and other sectors

Higr-preision filing

+ High-preisio filling

The line assures a high fling precision up to土1% (ilig quantity above 2ml) , benefiting from Truking's sterile liquid fling experience for nearly 20years, unique pumpback fligand anti-leakage control and good machining level

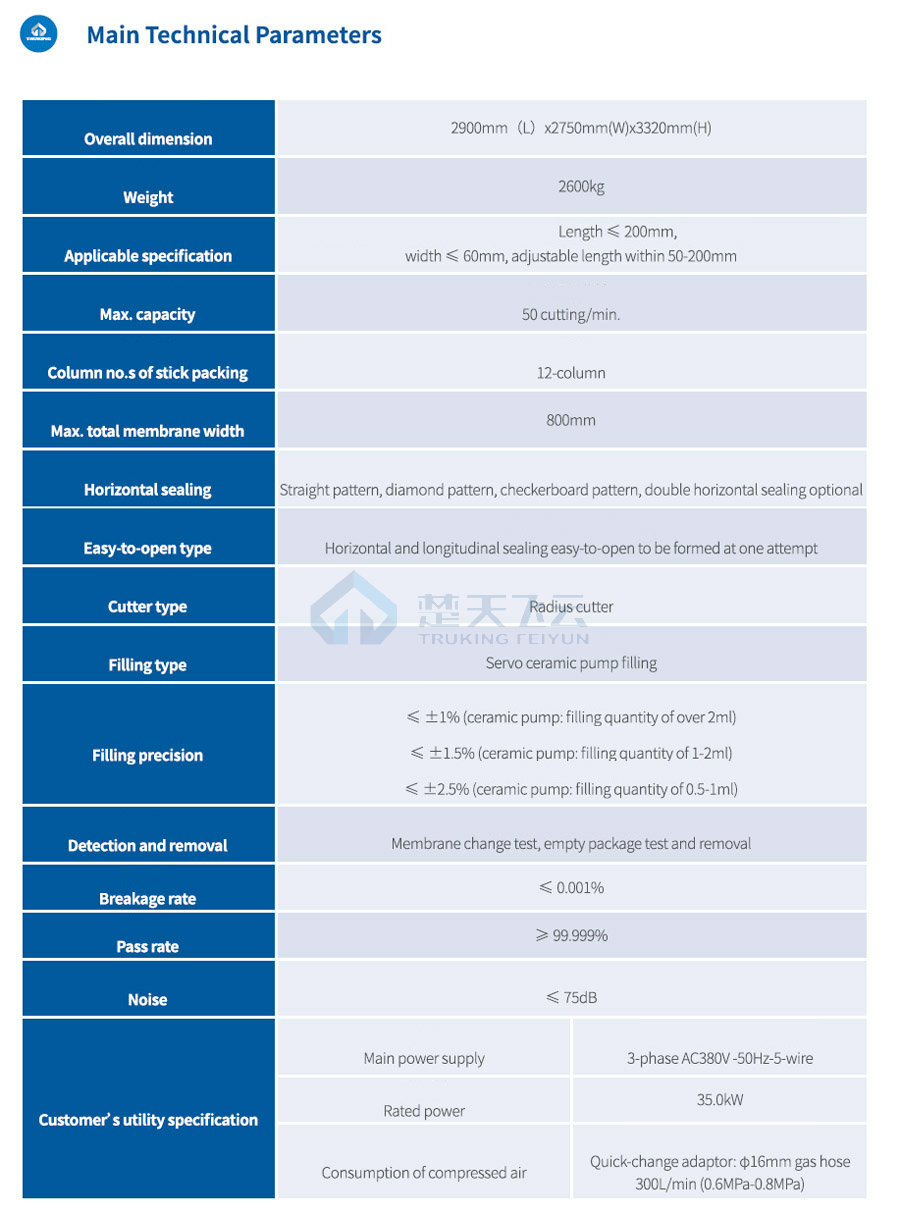

FiUngprecision

≤士1% (ceramic pump: flig quantity ofover 2ml)

≤+1.5%(ceramic pump: fligquantityof1-2ml)

≤+2.5% (ceramic pump:lling quantityof0.5-1ml)

+ Easyto open atone attempt, good user experience, low materialcost Horizontal and longitudinal easy openings are fomed in one mold to ensure that double easy openings stay at one straight line, thus improving user experienceand ensuring they are easy toopen.

+ Fullservo

Servo control applies to uncoiling, membrane misalignment correction, flling, longitudinal sealing, avoidance at specified locations, horizontalsealingmembrane drawingandfillet cuting

+ Straight guide rail

The slide guide moves across the straight line guide rail, featuring more advantages in transmission accuracy, loading stability and durability thanthe linear bearing

+ Easy toclean

Thelongitudinal and horizontal sealing mechanisms can be opened toallow thorough cleaning.

+ Easy to change the package widh and horizontal sealing pattern Adopt the modular design conducive to change to the horizontal pattern style and package width. lItis possible to allow complete change of appropriate mold for integral installation. This efficient work can benefit changeand installation at one attempt

+ Efective elimination ofliquid trappinginthe horizontalsealing Truking utlizes the liquid flig suction∞ntols to prevent dropping orleaking after fling

The servo fling step curve can controlfiling flowto prevent splash.

Stable and efficient

Truking boasts excellent manufacturing capability, who can independently complete machining of 90% parts to specified accuracy.

The hobbing cutter and radius cutter are made of high-speed steel.

The hot block for the longitudinal and horizontal sealing is made of chrome- manganese – silicon alloy.

Perform testing on element content of raw material.

The longitudinal and horizontal sealing has respective heating system, thus benefiting proper sealing from uniform distribution of heating.

Carry out avoidance at specified locations in the longitudinal sealing to protect the membrane from being distorted as a result of prolonged exposure to high-temp baking.

+ CIPSIP online cleaning optional

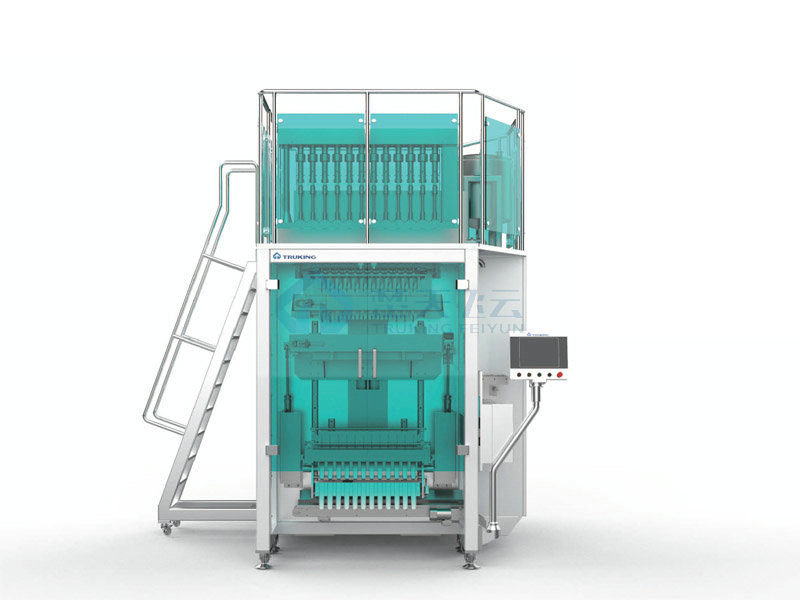

+ Large internal space

Large enough to accommodate coding machine and tester, thus facilitating operation and maintenance.

+ Independent servo flling, permitting separate change to flling

quantity

+ Use the transparent tempered glass protection door and low-counter designs. Plus, application of high-quality stainless steel and aluminum alloy can help assure uniform style, create a clean and tidy

environment and provide easy access to view. Provide machines of latest version.

+ 12” screen conducive to ergonomics-based HMI operation